Start your beamtime

Here is a short introduction to start the experiment. Please open the following three interfaces to view, move, control and scan the required (pseudo) motors in order to execute your experiment during the beamtime.

Scanning, for XAS-measurements (or RIXSmaps): Scangui

RIXSmeasurements: Rixsclient

Samples handling

At the RIXS endstation in Veritas beamline, you can carry out experiments with solid, liquid and gas samples. Here is a brief introduction of the sample environment, sample handling and preparation (particularly solid state samples).

Solid state samples

Get to know the endstation chambers

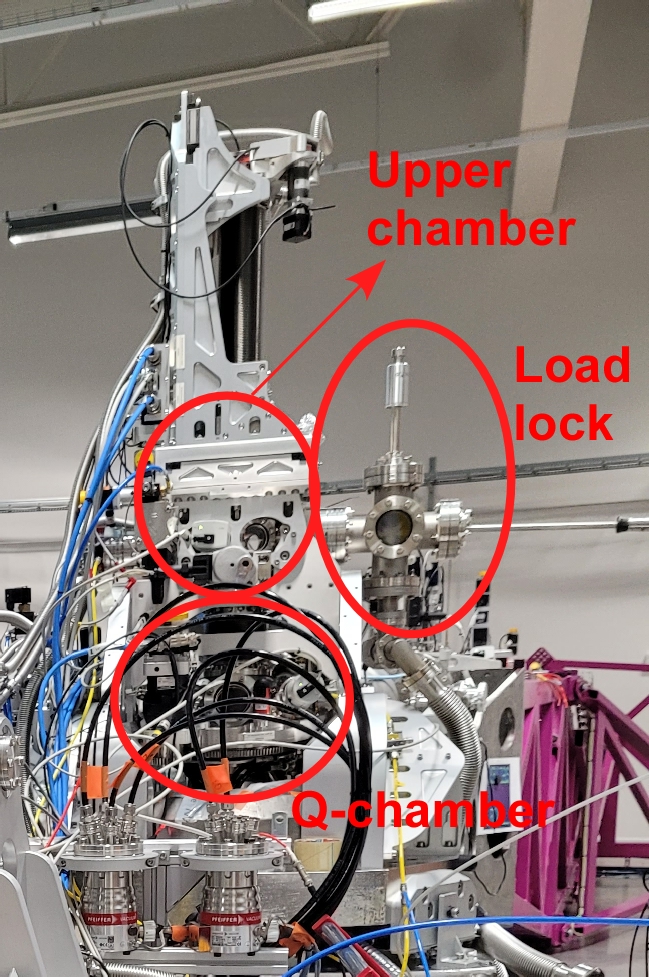

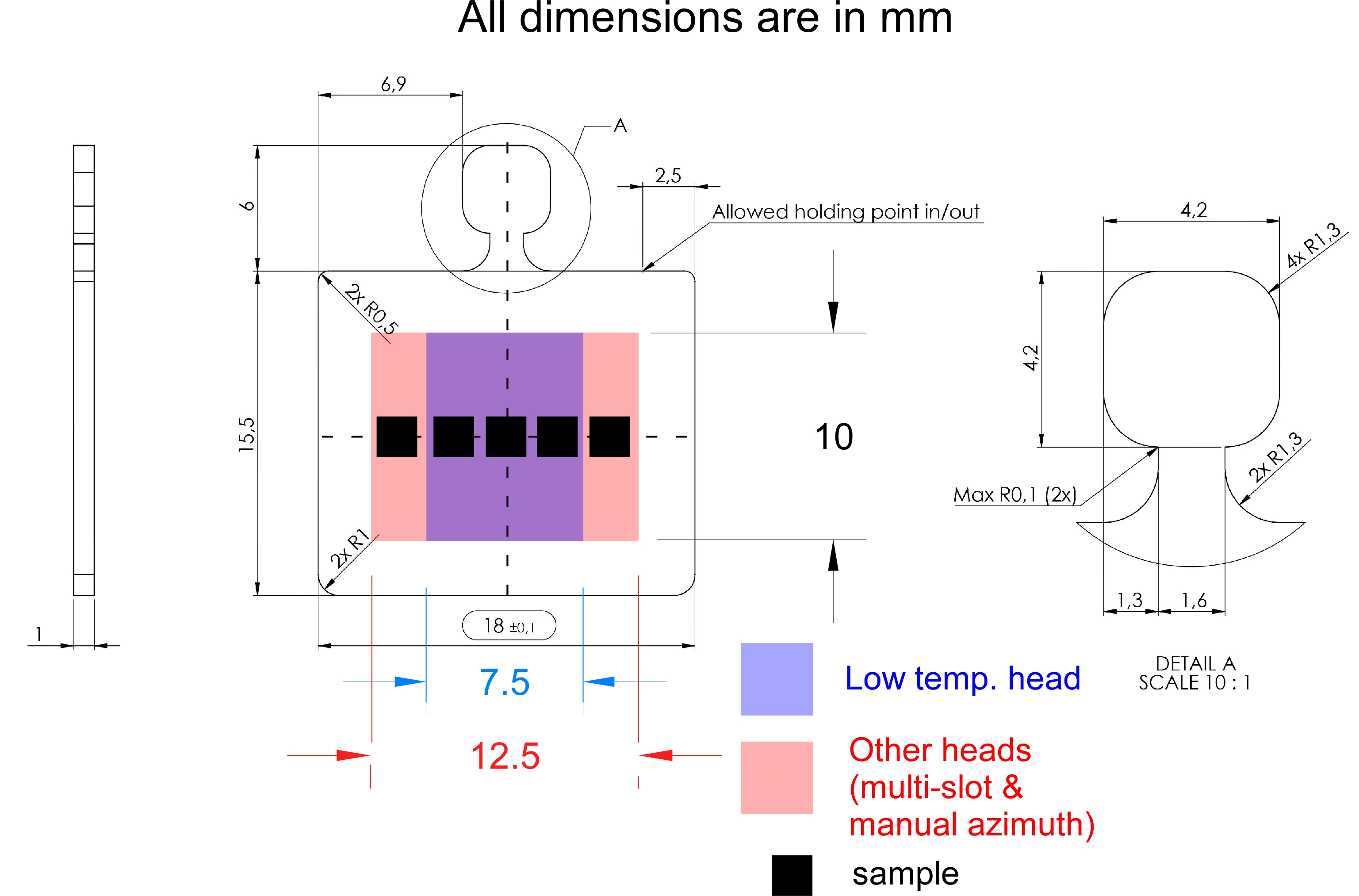

As already mentioned in the previous section, the Veritas RIXS endsation has three chambers, for solid and gas samples, as labled in the figure:

Load Lock (LL) chamber

Upper chamber or transfer chamber. This chamber receives the sample plate(s) from LL chamber. This chamber also houses the sample rod (which is also the closed cycle He cryostat).

Q-chamber or the measurement chamber. It allows continuous motion of the scattering arm without breaking the vacuum.

RIXS endstation chambers.

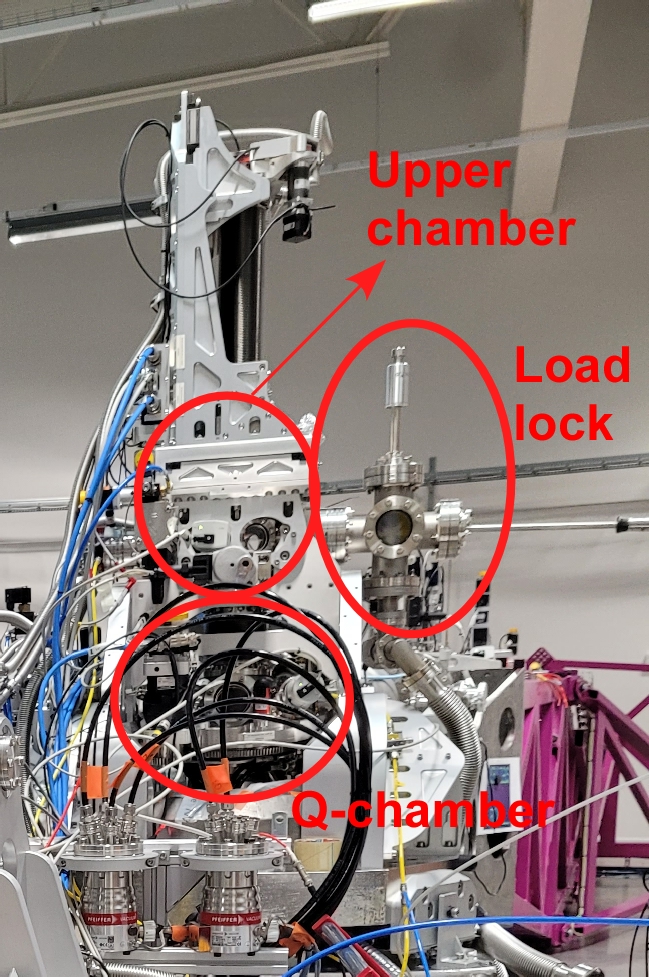

The solid samples can be in the form of powder (pelletized), single crystals or thin films. Here is a brief introduction of the steps you may follow to introduce your sample finally into the main chamber.

Here is a flowchart of the process that we usually follow.

Solid state sample handling.

NOTE: If your sample is air sensitive, you can use the argon suitcase and mount it directly on the load lock. To avail this, you must use the glove box facility available in one of the chemistry labs.

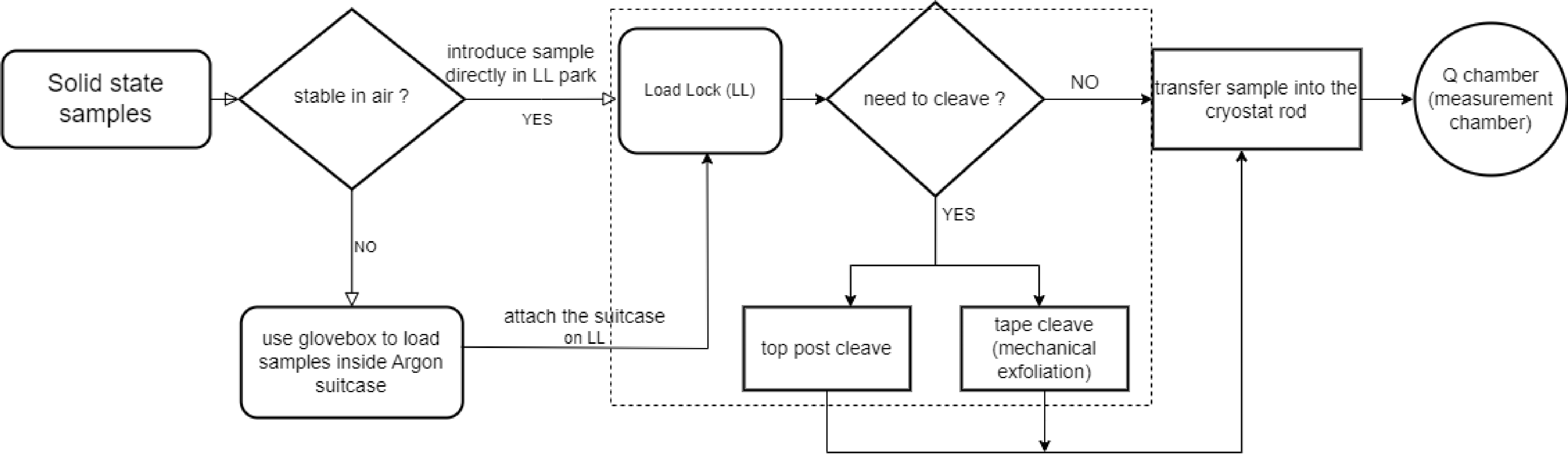

Sample plate

We use Omicron flag-style sample plate and the sample is glued on it either using both-side copper tape (if you are not cleaving the sample) or some conductive epoxy (example: Epotek H21D conductive epoxy, or Epotek E4110 conductive epoxy). Currently we have stainless steel and copper sample plates, and if you need, we can ship a few plates to the your address. For this, the you must approach the beamline responsible atleast one month ahead of the scheduled beamtime.

The sample gluing on the sample plate must be done within one of the shaded regions depending on the choice of cryostat head during experiment. You may glue multiple samples in one sample plate (if the azimuth cryo-head is not used), however, it is recommended to follow the orientation as shown in the figure.

Sample plate and sample gluing regions.

Load Lock

The load lock (LL) is attached to the upper chamber, and equipped with a linear transfer arm constituting of a sample bank to store four sample plates.

If your sample is air sensitive and cleaving may not be possible, please contact the beamline responsible and we will exchange the linear transfer system with an argon suitcase constituting of four sample plates bank. In this case, you, the user, may use Ar glove box available in one of the Chemistry labs at MAX IV to transfer samples into the samples plate bank of Ar suitcase. Purge the LL with Ar several times (5-6 times) before opening the suitcase valve, after which start the roughing pump followed by the turbo pump and wait till the pressure in LL is lower than 5 x 10^-7 mbar.

If you want to cleave the sample, you dont need to use the Ar suitcase. Introduce the sample plates from the LL door into the sample bank. After reaching appropriate pressure in the LL (lower than 5 x 10^-7 mbar), you may cleave with the transfer wobble stick.

How to Cleave ?

1. Top-post cleave Glue a post on the sample surface using conductive epoxy (example: Epotek H21D conductive epoxy, or Epotek E4110 conductive epoxy). It is recommended to use a post of similar surface area as that of the sample. Inside the LL, after reaching appropriate pressure, knock off the post using the transfer wobble stick to expose a clean sample surfece.

2. Tape cleave (mechanical exfoliation) You can also exfoliate the sample surface using tape (typically we use kaptone tape). See the figure.

Transfer sample to the sample rod in upper chamber

Now its time to transfer the sample plate(s) to the sample rod in the upper chamber (UC). Prior to transfer, the manipulator must be set to sample transfer positions in order to receive the sample plate. Let us know how to do this :

You need the following softwares to align the sample rod’s sample holder surface parallel to the sample plate:

Open these softwares

Prior to sample transfer and subsequent experiments lets open and get familiar with the following two control panels / softwares:

Sample transfer positions

The sample transfer will differ depending on the samplerod and environment currently in use. Please not the differences when indicated Please continue working on the list below.

Using the QuickGUI, Move manipulator to the following positions depending on the choice of the sample rod head:

Sample transfer positions for the low temperature head at 10 K:

Positions |

Low temperature head |

multi slot head |

azimuth head |

|---|---|---|---|

a_mp1_x |

66.65 mm |

||

a_mp1_y |

374 mm |

||

a_mp1_z |

17.5 mm |

||

a_mp1_yaw |

2 deg (tight/loose), 357 deg (to insert / remove sample plate) |

Transfer process: Follow the following steps to transfer the sample plate into the sample rod in the UC.

Close the valve between Q chamber and UC.

Check LL pressure is in the order of 10^-7 mbar.

Open the valve between the LL and UC.

Rotate the manipulator (a_mp1_yaw) to tight/loose position.

Tight/un-tight the screw holding the sample plate.

Remove if there is any sample in the sample rod and and park it in the LL sample garage.

Rotate the manipulator (a_mp1_yaw) to sample insert position.

Grab a new sample plate from LL garage.

Transfer it to the sample rod in the UC.

Rotate the manipulator (a_mp1_yaw) to tight/loose position.

Tight the screw.

Repeat the process between 5-11 if you have multiple samples.

Retract the transfer wobble stick and close the valve between LL and UC.

Open the valve between Q chamber and UC (safety feature: you cannot lower the manipulator if the valve is closed, yet its better to check and open the valve before lowering the manipulator).

Lower the manipulator to experimental position.

Now its time to find the samples. Go to “Finding samples” section.

Liquid samples

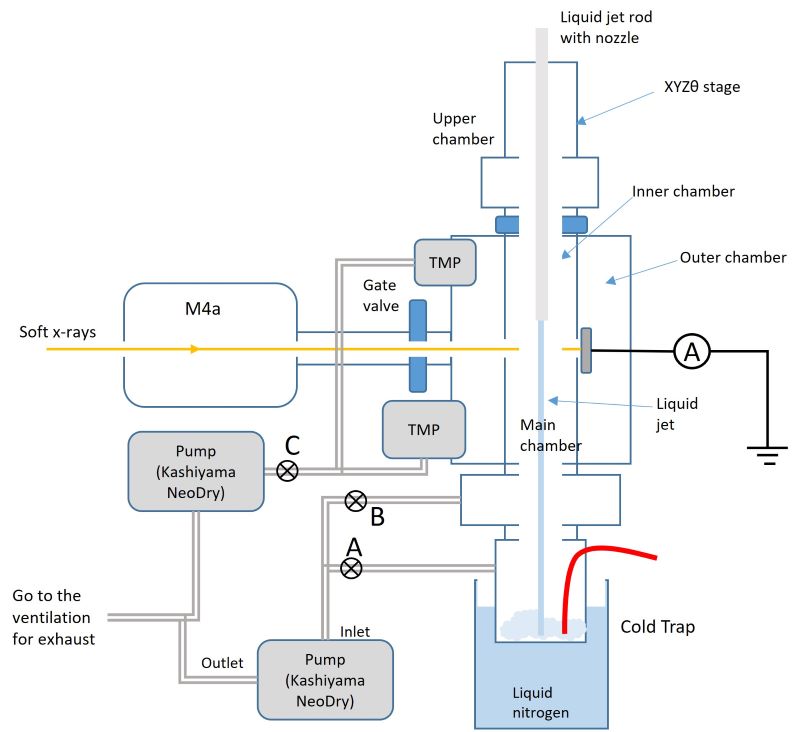

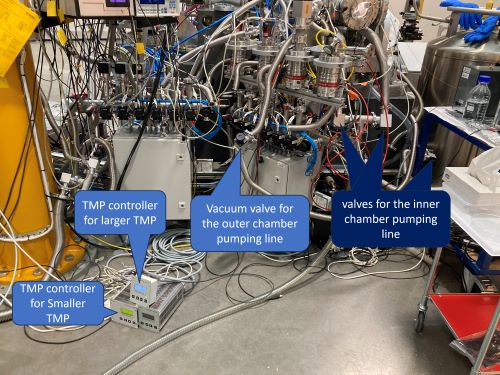

How to start pumping

Open angle valves (A and B) for inner chamber pumping. Wait for a min.

Open angle valve (C) for outer chamber pump.

Start two TMP for outer chamber pumping

Wait for the vacuum recovely

How to stop pumping

Confirm valves to beamline and emission specrometer is closed. it is recommended to close 3 valves from the endstation main chamber. if filter valve is used, remove filter( i.e. open filter valve) just after closing closing gate valves, to not make damage on the thin film window.

Close angle valve(C) for outer chamer pumping.

Close angle valve(B and C) for innter chamber pump.

Stop two TMPs for outer chamber pumping (and enable auto vent for larger TMP, if it is not enabled)

Wait for chmaber will be vent with air.

Procedure to Cleaning clod trap

The chamber is need to be in air pressure before starting. It is required to close top lid.

Prepare hot eater by a electric kettle. There is a black one with around 2l capacity and white smaller one. Cold trap capacity is around 4l, so do not put more than 2l of water.

remove or Lower the height of the nitrogen dewer under the cold trap. if there is remalind liquid N2. It is better not to remove cold trap since it is reqired to tilt the dewer to remove.

Add liquid nitrigen to the trap of the sample remover setup

Find a red line with a blank plug under cold trap. Connect a extension tube to the red tube line for put hot water into the cold trap.

Open the slow pumping line around B valves (in the schematic of endstation. pumping line with 6mm staine less tube) and slowly pump the chamber by kashiyama pump to let the cold trap to suck in the hot water. Wait for letting ice melt (around 3min). Keep through slow pumping line even after all water it goes in the cold trap. This will help not to feed the humid air to outer chamber.

Connect red line to the sample remover setup which is prepared beside M4 mirror of b branch.

Start the small pump of the sample remove setup and remove liquid from the cold trap. if glass canister becomes more than half. Stop pumping and exchange glass bin and continue pumping.

If cold trap still have ice go back to procedure no.5.

When all the sample is removed from cold trap. Put a blank plug to red line and seal it.

Detach glass canister of the sample remover, and store and despose them by following the camical related rules.

Start pumping and wait for vacuum recovery. intially, it will be around 1mbar, but it will be comes better after start cooling cold trap. Outer chamber shoud be around 2 to 6E-4 after start cooling of cold trap.

If innner and outer chamber vacuum is not beceoming better than 1mbar there is a lot of water somwehre in the chamber. Most case it is hote water spills in the pumping line from cold trap to the vacuum pump (large Kashiyama). Quick way to recover is echange NW25 hose.

Gas samples

Finding samples

Now its time to expose your sample to x-ray photons. Prior to this, check from synoptic if we have beam on the slit, and all the valves are open. If the sample rod is still in the UC, make sure to open the valve between Q-chamber and UC.

We first start with a 2D spatial map of the sample (a_mp1_x vs. a_mp1_y), after setting a_mp1_yaw at normal incidence. From this point on, you are going to use the control and acquisition software named ‘Scangui’. Here is how we do it:

Mesh scan

This is a 2D mapping of your sample using appropriate beamline energy. In the first attempt, the beamline energy does not need to be exactly the resonance energy, rather, any energy close to the resonant energy will work to get the contrast. You need to open these two softwares: Scangui and Sampletracker

After loading the sample down to the main chamber (we call it Q-chamber), you first begin with the mesh scan. This is how you can setup the mesh scan in Scangui:

go to ‘MacroExecutor’ or ‘Sequencer’ tab –> find ‘mesh’ macro from the ‘Macro’ dropdown list –> add it –> at the bottom, select the values ‘a_mp1_x’ and ‘a_mp1_y’ under parameters ‘motor1’ and ‘motor2’, respectively –> give start and final motors positions, nr_interval (number of steps), and integ_time. Set bidirectional to ‘true’ or ‘false’.

Linescan

With the Scangui, you can along x or y while reading an absorption intensity

From the quickgui: Write down current manipulator positions: a_mp1_x, a_mp1_y, a_mp1_z, and a_mp1_yaw

In the quickgui, choose an appropriate beamline_energy for getting contrast when you are on the sample

In the Scangui, select the measurement group “NEXAFS” (see details on how to change measurement group in the entry about the Scangui)

In the Scangui, go to basic executor select a_mp1_x or a_mp1_y and scan around your starting guess

In the Scangui, plot a_mp1_x towards the appropriate alba elektrometer signal

Calibrating the emission spectrometer

See the entry under RIXS client